| $ontext

Job Shop Scheduling

Manne formulation

Alan Manne, "On the job-shop scheduling problem", Operations Research

vol 8, no 2 March-April 1960.

Data set ft10 is from:

H. Fisher, G. L. Thompson, Probabilistic learning combinations of

local job-shop scheduling rules, in: J. F. Muth, G. L. Thompson (eds.),

Industrial Scheduling, Prentice Hall, Englewood Cliffs, N.J., 1963.

job1: 0 29 ; 1 78 ; 2 9 ; 3 36 ; 4 49 ; 5 11 ; 6 62 ; 7 56 ; 8 44 ; 9 21

job2: 0 43 ; 2 90 ; 4 75 ; 9 11 ; 3 69 ; 1 28 ; 6 46 ; 5 46 ; 7 72 ; 8 30

job3: 1 91 ; 0 85 ; 3 39 ; 2 74 ; 8 90 ; 5 10 ; 7 12 ; 6 89 ; 9 45 ; 4 33

job4: 1 81 ; 2 95 ; 0 71 ; 4 99 ; 6 9 ; 8 52 ; 7 85 ; 3 98 ; 9 22 ; 5 43

job5: 2 14 ; 0 6 ; 1 22 ; 5 61 ; 3 26 ; 4 69 ; 8 21 ; 7 49 ; 9 72 ; 6 53

job6: 2 84 ; 1 2 ; 5 52 ; 3 95 ; 8 48 ; 9 72 ; 0 47 ; 6 65 ; 4 6 ; 7 25

job7: 1 46 ; 0 37 ; 3 61 ; 2 13 ; 6 32 ; 5 21 ; 9 32 ; 8 89 ; 7 30 ; 4 55

job8: 2 31 ; 0 86 ; 1 46 ; 5 74 ; 4 32 ; 6 88 ; 8 19 ; 9 48 ; 7 36 ; 3 79

job9: 0 76 ; 1 69 ; 3 76 ; 5 51 ; 2 85 ; 9 11 ; 6 40 ; 7 89 ; 4 26 ; 8 74

job10: 1 85 ; 0 13 ; 2 61 ; 6 7 ; 8 64 ; 9 76 ; 5 47 ; 3 52 ; 4 90 ; 7 45

Description: jobs need to follow a sequence of operations. The numbers indicate

machine number and processing time.

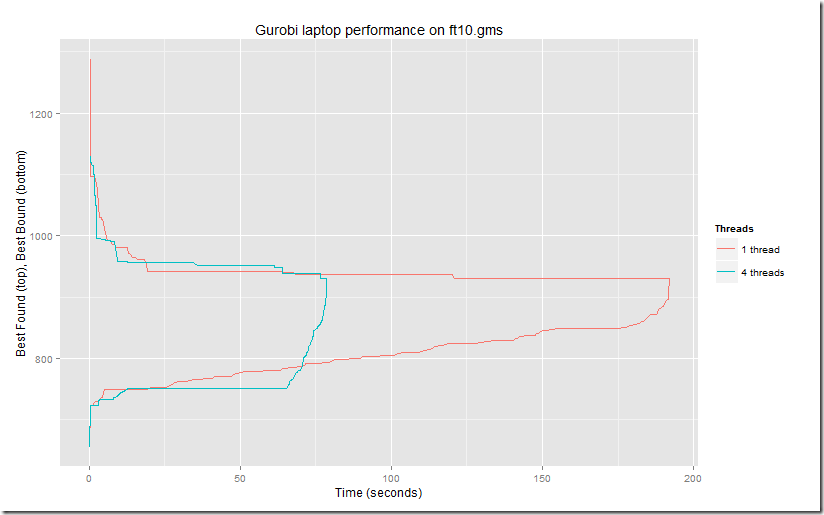

This is a well-known benchmark problem and the optimal obj=930.

$offtext

set

j 'tasks' / job1*job10/

t 'stages' /t1*t10/

;

table proctime(j,t) 'processing times for each stage'

t1 t2 t3 t4 t5 t6 t7 t8 t9 t10

job1 29 78 9 36 49 11 62 56 44 21

job2 43 90 75 11 69 28 46 46 72 30

job3 91 85 39 74 90 10 12 89 45 33

job4 81 95 71 99 9 52 85 98 22 43

job5 14 6 22 61 26 69 21 49 72 53

job6 84 2 52 95 48 72 47 65 6 25

job7 46 37 61 13 32 21 32 89 30 55

job8 31 86 46 74 32 88 19 48 36 79

job9 76 69 76 51 85 11 40 89 26 74

job10 85 13 61 7 64 76 47 52 90 45

;

table machine(j,t) 'machine numbers for each stage (zero based)'

t1 t2 t3 t4 t5 t6 t7 t8 t9 t10

job1 0 1 2 3 4 5 6 7 8 9

job2 0 2 4 9 3 1 6 5 7 8

job3 1 0 3 2 8 5 7 6 9 4

job4 1 2 0 4 6 8 7 3 9 5

job5 2 0 1 5 3 4 8 7 9 6

job6 2 1 5 3 8 9 0 6 4 7

job7 1 0 3 2 6 5 9 8 7 4

job8 2 0 1 5 4 6 8 9 7 3

job9 0 1 3 5 2 9 6 7 4 8

job10 1 0 2 6 8 9 5 3 4 7

;

alias (j,j2),(t,t2);

set ovl(j,t,j2,t2) 'this subset of (j,t),(j2,t2) needs to be checked against overlap';

ovl(j,t,j2,t2)$(ord(j)<ord(j2) and machine(j,t)=machine(j2,t2)) = yes;

variables

x(j,t) 'start time of subtask'

y(j,t,j2,t2) 'binary variable to implement non-overlap: (j,t) before or after (j2,t2)'

z 'objective variable'

;

binary variable y;

positive variable x;

scalar TMAX 'max time horizon';

TMAX = sum((j,t), proctime(j,t));

equations

NoOverlap1(j,t,j2,t2) 'machine overlap'

NoOverlap2(j,t,j2,t2) 'machine overlap'

Precedence(j,t) 'orders need to follow a certain sequence of machines'

zmax(j,t) 'make span'

;

*

* each task within a job should start after previous one has finished

*

Precedence(j,t)$(ord(t)<card(t)).. x(j,t+1) =G= x(j,t) + proctime(j,t);

*

* tasks on a machine cannot overlap:

* execute either before or after

*

NoOverlap1(ovl(j,t,j2,t2)).. x(j2,t2) =G= x(j,t) + proctime(j,t) - TMAX*y(j,t,j2,t2);

NoOverlap2(ovl(j,t,j2,t2)).. x(j,t) =G= x(j2,t2) + proctime(j2,t2) - TMAX*(1-y(j,t,j2,t2));

*

* minimize completion time of last task

*

zmax(j,t).. z =G= x(j,t) + proctime(j,t);

option optcr=0;

model jobshop /all/;

solve jobshop minimizing z using mip; |

Hi Erwin,

ReplyDeleteI am looking for an algorithm to deal with Job-shop scheduling as a constraint programming. I can't use commercial solvers.

Any chance you might have faced with this issue ?

I need to solve the large scale problem in a quick time (find a feasible solution no matter it is optimal or not)